-

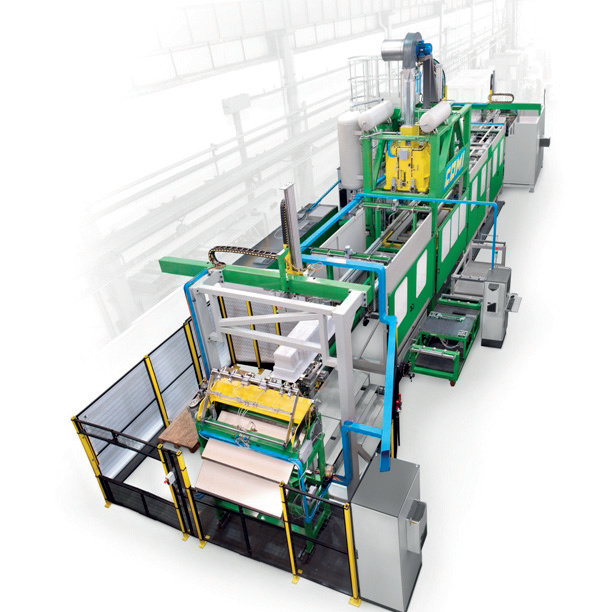

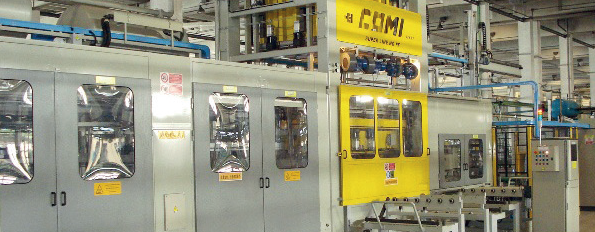

The thermoforming machines mod. BasicLine and Superline of New Generation line are composed of a series of in line stations which make the forming process fully automatic.

They are suitable to work plastic material in sheet in automatic cycle (ABS and HIPS) with thickness from 0,5 up to8 mm.

It is a universal system suited for the production of household refrigerator inner doors and liners, which does not need anyadditional adjustment.

The forming process is obtained through the establishment of vacuum in the mould, while the bubble stage of the material is executed by a “bell” located in the upper section of the forming station.

All the displacements are made by the Servomotor and thefunctions, fully automatic, are handled by the operator panel.

Different type of heaters are applicable: ceramic, quartzor fl ash back (black ceramic) and you can use positive and negative moulds.

All in line COMI machines are planned to be integrated into the production lines of the customers. They can be equipped with a series of optionals which increase productivity and efficiency in accordance with the customers’ requirements.COMI in line machines can match the whole mechanical systems of cutting and drilling.Furthermore, through TechMill, it is possible to provide CNC Milling machines, WaterJet or Laser Cutting machine for the finishing of the pieces.

Production speed BasicLine and SuperLine New Generation

Inner liners

doors

HIPS

3,5 mm

Up to 130 pcs/h

HIPS

1,2 mm

Up to 250 pcs/h

ABS

2,8 mm

Up to 130 pcs/h

ABS

1,0 mm

Up to 250 pcs/h

Standard dimensions

2000x900x600* mm

2000x1000x600* mm

2100x1250x600* mm

2200x900x600* mm

2200x1000x600* mm

depth of the moulded pieces available up to 800 mm

PRODUCTS